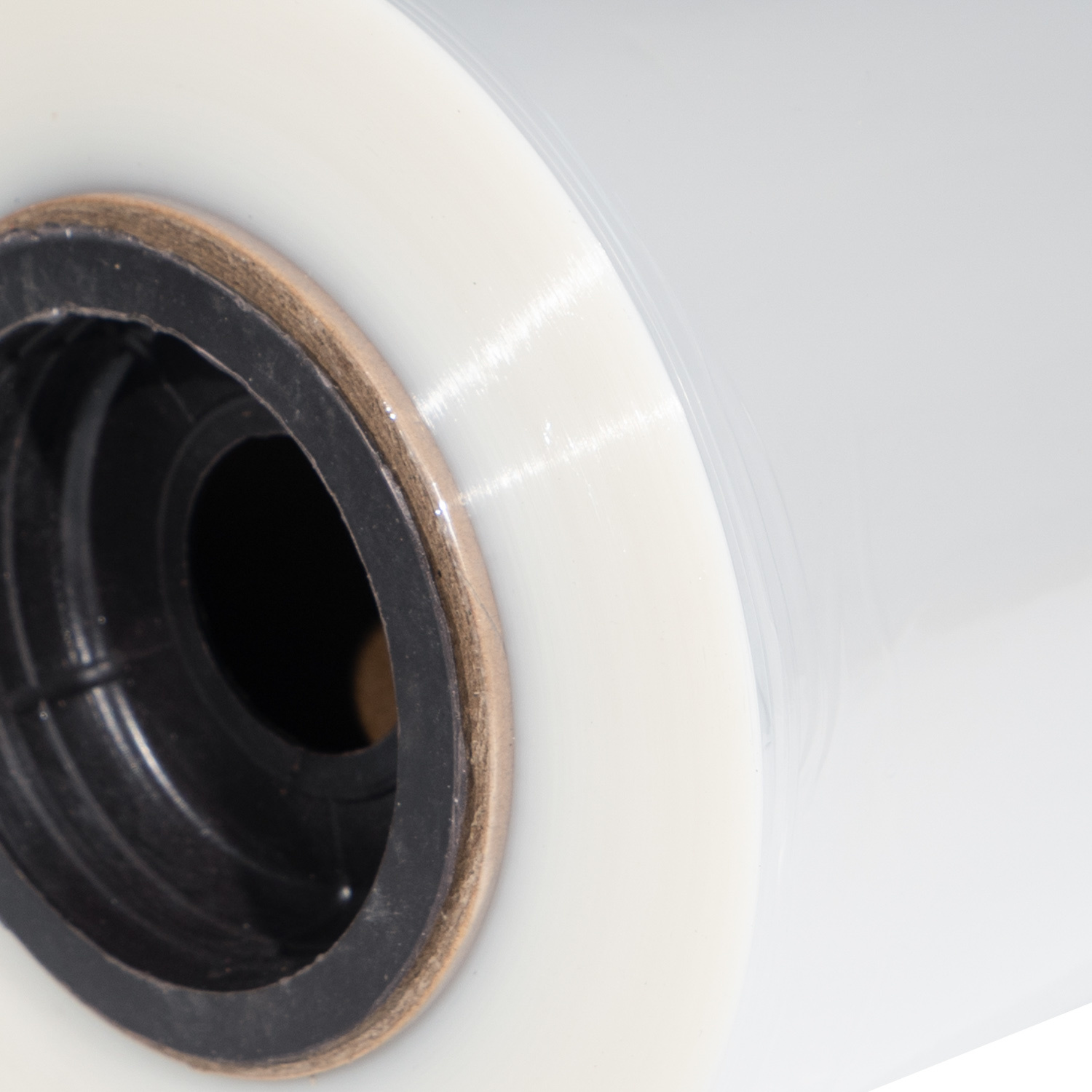

Mini stretch film

Share To:

Wrapping film is a new type of packaging material made from LLDPE. It is a plastic film with adhesive properties on one or both sides, which can be stretched and tightly wrapped around the wrapped item. It has the characteristics of high tensile strength, high elongation, good self-adhesion, high transparency, and high tear resistance. Therefore, it can wrap the object into a whole and prevent it from scattering and collapsing during transportation. This film wraps objects in a beautiful and elegant manner, and can prevent moisture, dust, and damage. It has a low cost of use and is widely used for pallet packaging of goods, such as electronic building materials, chemicals, metal products, automotive parts, wires, cables, paper products, daily necessities, food and other industries. The combination of hand film and slitting film with a film puller makes packaging more convenient.

Category:

Stretch film

Keywords:

Mini stretch film

Product Details

Wrapping film is a new type of packaging material made from LLDPE. It is a plastic film with adhesive properties on one side, which can be stretched and tightly wrapped around the wrapped item. It has the characteristics of high tensile strength, high elongation, good self-adhesion, high transparency, and high tear resistance. Therefore, it can wrap the object into a whole and prevent it from scattering and collapsing during transportation. This film wraps objects in a beautiful and elegant manner, and can prevent moisture, dust, and damage. It has a low cost of use and is widely used for pallet packaging of goods, such as electronic building materials, chemicals, metal products, automotive parts, wires, cables, paper products, daily necessities, food and other industries.

Stretch Wrap Film - Features

High strength, good elongation, good self-adhesion, tear resistance, easy to use, cost-effective, odorless, and non-toxic.

Stretch Wrap Film - Application

Stretching film is widely used in export, carton, tray, building materials, fertilizer, cement, clothing, automobile, glass fiber, ceramics, transportation and other fields.

Stretch Wrap Film - Classification

According to the classification of purposes, it can be divided into manual stretch wrap films, machine use stretch film, banding film, jumbo roll, colored stretch film, and ventilated stretch film.

Physical and mechanical properties of the product

|

Thickness range |

Tensile strength |

Elongation at break (longitudinal, transverse) |

Angle tear strength (longitudinal, transverse) |

Self-adhesive |

Pendulum impact capability |

|

At |

Mpa≥ |

%≥ |

N/mm≥ |

N/cm ≥ |

I ≥ |

|

15-19 |

38 |

300、600 |

120 |

3.0 |

0.15 |

|

20-25 |

39 |

300、600 |

120 |

3.0 |

0.46 |

|

26-35 |

40 |

300、600 |

120 |

3.0 |

0.19 |

|

36-50 |

41 |

300、600 |

120 |

3.0 |

0.21 |

|

specification |

width |

length |

thickness |

pulling force |

Paper core inner diameter |

color |

|

Hand stretch film |

100-1000MM |

100M-1000M |

8-40MIC |

More than 300%. |

38MM,50MM,76MMM |

Transparent, milky white, red, green, black, blue and other customized colors |

|

Machine wound film |

200-1000MM |

100M-5000M |

10-50MIC |

More than 300%. |

50MM,76MM |

Can be customized according to customer requirements |

|

Slitting membrane |

70-300MM |

100M-1000M |

10-50MIC |

More than 350%. |

38MM,50MM |

Transparent, milky white, red, green, black, blue and other customized colors |

|

Wrapped film mother roll |

500-1500MM |

500M-5000M |

8-50MIC |

More than 300%. |

76MM |

Transparent, milky white, red, green, black, blue and other customized colors |

|

Color wrapping film |

100-1000MM |

100M-1000M |

8-40MIC |

More than 300%. |

38MM, 50MM, 76MM |

Transparent, milky white, red, green, black, blue and other customized colors |

|

Breathable wrapping film |

100-1000MM |

100M-1000M |

15-40MIC |

More than 250%. |

38MM, 50MM, 76MM |

Transparent and other custom colors |

01- Stretch film - features

High strength, good elongation, good self-adhesiveness, tear resistance, easy to use, cost-effective, tasteless, non-toxic.

02- Stretch film - application

Stretch film is widely used in foreign trade export, cartons, pallets, building materials, fertilizer, cement, clothing, automobile, glass fiber, ceramics, transportation industry and other fields.

03- Stretch film - classification

According to the classification of use, the stretch film is divided into manual stretch film, machine stretch film, banding film, jumbo roll, color stretch film, ventilated stretch film.

Mini stretch film is a specialized and compact version of traditional stretch film. It is designed to meet the unique packaging needs of smaller items or in situations where space is limited.

This film offers several key features and benefits. Firstly, it has excellent stretchability, allowing it to conform snugly to the contours of the objects being wrapped. This ensures a secure and tight packaging that protects the items from damage during handling and transportation.

The mini size of the film makes it highly versatile and suitable for a wide range of applications. It can be used for packaging individual products, small bundles, or for protecting delicate components. It is often preferred in industries where precision and careful packaging are crucial, such as electronics, jewelry, or small consumer goods.

One of the notable advantages of mini stretch film is its convenience. It is easy to handle and manipulate, even in smaller workspaces. It can be quickly applied without the need for complex machinery or extensive training.

The film also provides good clarity, allowing for clear visibility of the packaged items. This is important for inspection purposes or when the appearance of the product needs to be showcased.

In addition to its functional qualities, mini stretch film is often available in different colors. This can be useful for coding or marking purposes, making it easier to identify and sort the packaged items.

Despite its smaller size, mini stretch film still maintains a high level of durability. It is resistant to tears and punctures, ensuring the integrity of the packaging. It can also withstand various environmental conditions, such as temperature changes and humidity.

Industries that benefit from mini stretch film include retail, where it is used for packaging small items for display or sale. Warehousing and distribution centers also utilize it for packaging and organizing smaller shipments. Laboratories and medical facilities may use it to protect sensitive equipment or samples.

The compact nature of mini stretch film makes it an efficient packaging solution that saves space and reduces waste. It is an ideal choice for those looking for a practical and effective way to package smaller items with ease and convenience. With its combination of functionality, versatility, and user-friendliness, mini stretch film is a valuable asset in many different packaging scenarios. It helps ensure the safety and presentation of small products while optimizing packaging processes.

Releated Product

Inquiry