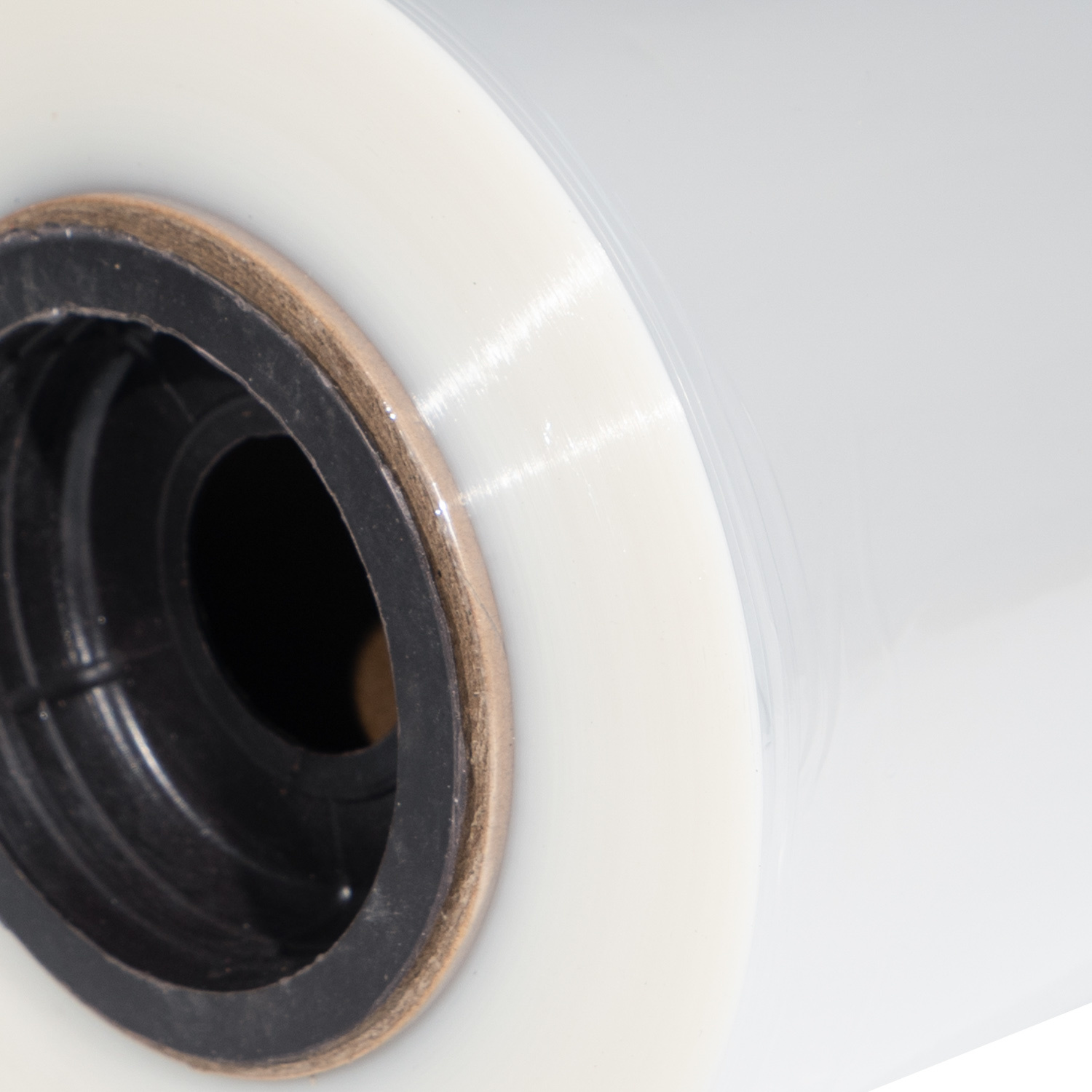

Plastic packaging film

Share To:

PE flat bags are made of polyethylene (LDPE) and high-pressure linear polyethylene (LLDPE) through blow molding and hot cutting, making them a plastic bag that can be repeatedly sealed. Plastic packaging film is a widely used and essential material in various industries. The term "Plastic packaging film" accurately describes its main purpose and function.

Category:

Plastic bag

Keywords:

Plastic packaging film

Product Details

Plain Polybag is a plastic bag that can be recycled by blowing film molding and hot-cutting machine.

Plain Polybag - specification

Length, width and thickness, can be customized according to customer requirements. Colored plain polybag can be made. It can print according to customer requirements.

PE plain polybag - features

1. PE polybag can be used for the inner and outer packaging of various small items (accessories, small hardware, toys). It can use food grade raw material to wrap food.

2. PE polybag can be produced by adding anti-static raw material, which is generally used in the electronics industry;

3. PE polybag is pollution-free, strong and durable;

4. PE polybag has excellent characteristics such as stretchability, retraction, high transparency, waterproof and moisture-proof. At the same time, the products have been tested by a number of instruments and professionals to ensure high standards of quality.

01- PE polybag - features

PE polybags can be used for the inner and outer packaging of various small items (accessories, small hardware, toys); It can also add anti-static raw material to form anti-static polybag, which is generally used in the electronics industry; PE polybag has excellent characteristics such as stretchability, retraction, high transparency, waterproof and moisture-proof.

02- PE polybag - specification

Length, width and thickness, can be customized according to customer requirements. Colored polybag can be made. Printing can be made.

03- PE polybag - formation

Blowing film molding and hot cutting machine.

Plastic packaging film is a widely used and essential material in various industries. The term "Plastic packaging film" accurately describes its main purpose and function.

This thin and flexible film is known for its excellent protective qualities. It acts as a barrier, safeguarding the contents from external elements such as moisture, dust, and physical damage. This is crucial for preserving the integrity and quality of the packaged items.

The plastic used in these films is often selected for its durability and strength. It can be stretched and molded to fit snugly around different shapes and sizes of products, providing a secure packaging solution. Different types of plastic, such as polyethylene or polypropylene, are commonly used, each with its own unique properties.

One of the significant advantages of plastic packaging film is its transparency. This allows consumers to clearly see the product inside without having to open the packaging. It enhances the visual appeal and helps in marketing and display.

The film can also be printed on, enabling branding, instructions, and important information to be easily visible. This adds a marketing aspect to the packaging and helps in communicating with the end-users.

In the food industry, plastic packaging film plays a vital role. It keeps food fresh, extends its shelf life, and protects it from spoilage. Specialized films may have properties like oxygen barrier or moisture resistance to meet the specific requirements of different food types.

For non-food items, it provides protection during storage, transportation, and handling. It prevents scratches, dents, and other damages that could occur during these processes.

Plastic packaging film is also highly versatile. It can be used in various forms, such as rolls, bags, or shrink films. Shrink films, in particular, conform tightly to the shape of the product when heated, providing a secure and tamper-proof seal.

It is cost-effective and easy to manufacture in large quantities, making it accessible for a wide range of applications. However, there are also concerns regarding its environmental impact. The improper disposal of plastic packaging film can lead to pollution and contribute to the growing problem of plastic waste.

To address these concerns, efforts are being made to develop more sustainable and eco-friendly alternatives. This includes biodegradable or recyclable plastic films, as well as exploring new materials and technologies.

In conclusion, plastic packaging film is an indispensable material in modern packaging. It offers protection, visibility, and convenience. While its environmental impact is a matter of concern, ongoing research and innovation are working towards finding more sustainable solutions. Plastic packaging film continues to play a crucial role in various industries, ensuring that products reach consumers in the best possible condition. Plastic packaging film, Plastic packaging film, Plastic packaging film.

Releated Product

Inquiry