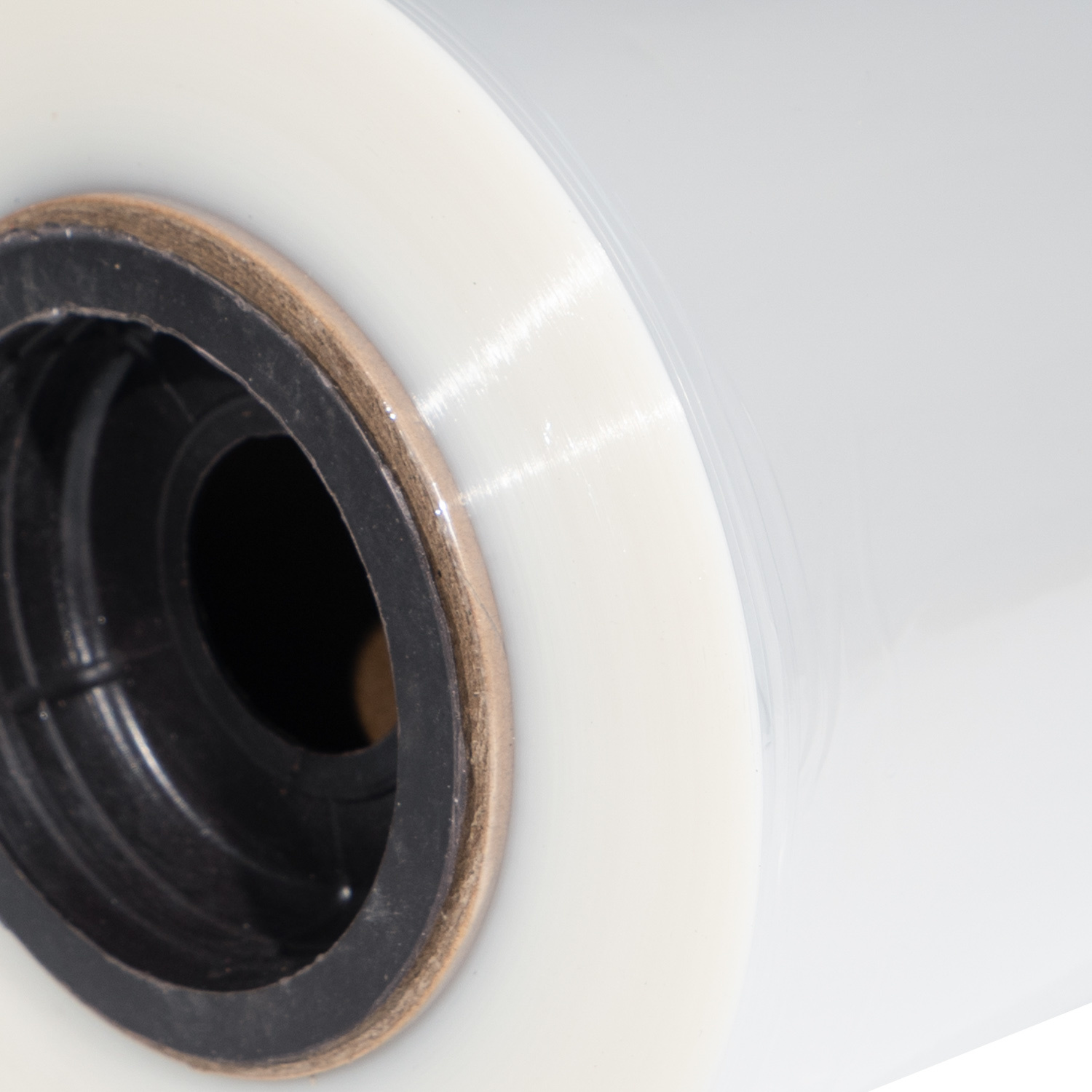

Plastic roll

Share To:

PE flat bags are made of polyethylene (LDPE) and high-pressure linear polyethylene (LLDPE) through blow molding and hot cutting, making them a plastic bag that can be repeatedly sealed. Plastic roll is a highly versatile and widely used product in many industries. The name "Plastic roll" accurately conveys its basic form.

Category:

Plastic bag

Keywords:

Plastic roll

Product Details

Plain Polybag is a plastic bag that can be recycled by blowing film molding and hot-cutting machine.

Plain Polybag - specification

Length, width and thickness, can be customized according to customer requirements. Colored plain polybag can be made. It can print according to customer requirements.

PE plain polybag - features

1. PE polybag can be used for the inner and outer packaging of various small items (accessories, small hardware, toys). It can use food grade raw material to wrap food.

2. PE polybag can be produced by adding anti-static raw material, which is generally used in the electronics industry;

3. PE polybag is pollution-free, strong and durable;

4. PE polybag has excellent characteristics such as stretchability, retraction, high transparency, waterproof and moisture-proof. At the same time, the products have been tested by a number of instruments and professionals to ensure high standards of quality.

01- PE polybag - features

PE polybags can be used for the inner and outer packaging of various small items (accessories, small hardware, toys); It can also add anti-static raw material to form anti-static polybag, which is generally used in the electronics industry; PE polybag has excellent characteristics such as stretchability, retraction, high transparency, waterproof and moisture-proof.

02- PE polybag - specification

Length, width and thickness, can be customized according to customer requirements. Colored polybag can be made. Printing can be made.

03- PE polybag - formation

Blowing film molding and hot cutting machine.

Plastic roll is a highly versatile and widely used product in many industries. The name "Plastic roll" accurately conveys its basic form.

These rolls are typically made of various types of plastic, such as polyethylene, polypropylene, or PVC. The choice of plastic depends on the specific requirements of the intended application.

One of the main advantages of plastic rolls is their flexibility. They can be easily unrolled and cut to the desired length or shape, making them suitable for a wide range of packaging and covering needs.

In the packaging industry, plastic rolls are often used to create bags, pouches, or wraps. They provide a convenient and cost-effective way to protect and store various items. The plastic can be transparent, allowing for easy identification of the contents, or it can be colored or printed for branding and marketing purposes.

Plastic rolls are also used in construction and DIY projects. They can act as a moisture barrier or a protective covering for floors, walls, or equipment. Some types of plastic rolls are even designed to have specific properties like insulation or fire resistance.

In the manufacturing sector, they play a crucial role in processes such as extrusion and laminating. Plastic films or sheets can be produced from these rolls, which are then used in the production of a variety of products, including containers, packaging materials, and industrial components.

The durability of plastic rolls is another significant factor. They are resistant to many environmental factors, such as moisture, chemicals, and abrasions. This makes them suitable for both indoor and outdoor applications.

The thickness and width of plastic rolls can vary greatly, depending on the intended use. Thinner rolls may be used for lightweight packaging, while thicker ones are more suitable for heavier-duty applications.

Plastic rolls are also relatively easy to handle and store. They can be rolled up tightly and take up minimal space when not in use. This makes them a practical choice for businesses and individuals who need a flexible and accessible packaging solution.

However, like many plastic products, plastic rolls also have some environmental concerns. The improper disposal of plastic waste can have a negative impact on the environment. To address this, efforts are being made to increase recycling and the use of more sustainable plastic materials.

In conclusion, plastic roll is a valuable and essential product in various industries. Its flexibility, durability, and ease of use make it a popular choice for packaging, construction, and manufacturing applications. Despite the environmental challenges, ongoing research and innovation are working towards finding more eco-friendly solutions. Plastic roll continues to be an important material in our daily lives and industries. Plastic roll, Plastic roll, Plastic roll.

Releated Product

Inquiry