Shrink film food grade

Share To:

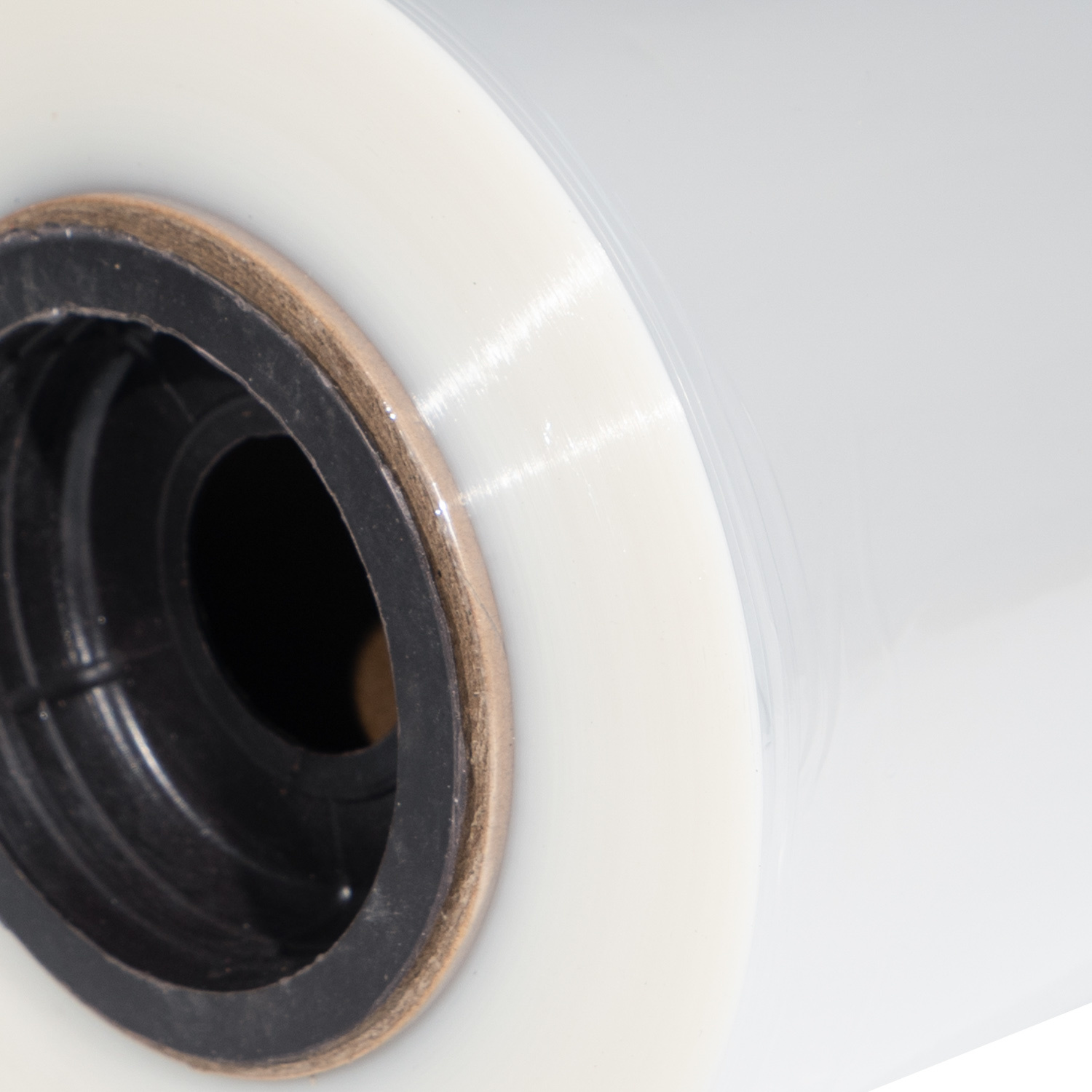

POF shrink film is a heat shrink film made by using linear low density polyethylene (LLDPE) as the intermediate layer and co polypropylene (PP) as the inner and outer layers in specialized equipment. The inner, middle, and outer layers are extruded together through a special process, resulting in high transparency, high shrinkage rate, and good heat sealing performance.

Category:

Shrink Film

Keywords:

Shrink film food grade

Product Details

POF shrink film uses LLDPE as the intermediate layer, polypropylene as the inner and outer layers. By special equipment, the inner, middle and outer layers are extruded together by a special process, and the heat shrinkable film with high transparency, high shrinkage rate and good heat sealing performance is made. It has all the advantages and advantages of polyethylene (PE) and polypropylene (PP), and its excellent performance is far better than simple polyethylene (PE) film and polypropylene (PP) film, which is currently widely used internationally and recognized by the European and American market protection heat shrinkable packaging materials.

It complies with US FDA and USDA standards, is all made of environmentally friendly materials, and is an environmentally friendly packaging material that can be recycled and reused. Especially suitable for pharmaceutical industry and food industry. The product meets "GMP" requirements.

POF shrink film - application industry

Automotive supplies, plastic products, stationery, books, electronics, circuit boards, MP3, VCD, handicrafts, photo frames and other wood products, toys, pesticides, daily necessities, food, cosmetics, canned beverages, dairy products, medicine, cassettes and video tapes, etc.

POF shrinkable film-features

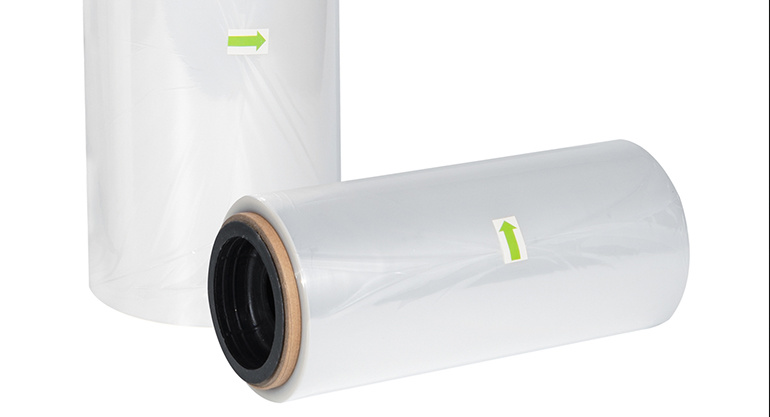

1. High transparency, good gloss, can clearly display the appearance of the product, improve sensory awareness, reflect high grade.

2. Large shrinkage rate, up to 75%, good flexibility, can be packaged for any shape of goods, and the shrinkage force of the three-layer coextruded film after special process treatment is controllable to meet the requirements of shrinkage force of different commodity packaging.

3. Good welding and sealing performance, high strength, suitable for manual, semi-automatic and high-speed automatic packaging.

4. Good cold resistance, can maintain flexibility at -50 °C without brittleness, suitable for storage and transportation of packaged materials in cold environments.

5. Environmental protection and non-toxic, in line with the US FDA and USDA standards, can package food.

01- POF shrink film - application industry

Automotive supplies, plastic products, stationery, books, electronics, circuit boards, MP3, VCD, handicrafts, photo frames and other wood products, toys, pesticides, daily necessities, food, cosmetics, canned beverages, dairy products, medicine, cassettes and video tapes, etc.

02- POF shrinks the film - formation

It is a heat shrinkable film with high transparency, high shrinkage and good heat sealing performance by using linear low-density polyethylene (LLDPE) as the intermediate layer and copolypropylene (PP) as the inner and outer layers in special equipment, and the inner, middle and outer layers are extruded together by a special process.

03- POF shrink film - features

High transparency, good gloss; Large shrinkage, up to 75%, good flexibility, can be packaged for any shape of goods; Good welding performance and high strength; Good cold resistance; Eco-friendly and non-toxic, in line with the US FDA and USDA standards, can package food.

### Detailed Description of Shrink Film Food Grade

Shrink film food grade is an essential packaging material widely used in the food industry due to its excellent properties and versatility. This specialized type of shrink film is meticulously crafted to meet stringent food safety standards, ensuring that it does not leach harmful chemicals or contaminants into the food it encases.

Key characteristics of shrink film food grade include its exceptional clarity, which allows for perfect product visibility, thereby enhancing the visual appeal of packaged food items. The film's high tensile strength provides robust protection against physical damage, moisture, and dust ingress, significantly extending the shelf life of perishable goods. Additionally, its conformability enables a tight, streamlined wrap that not only secures the contents but also contributes to an aesthetically pleasing presentation on store shelves.

The heat-shrinkable feature of this food-grade film is optimized for efficiency, allowing it to uniformly shrink around irregularly shaped products when exposed to controlled heat. This property ensures a snug fit, reducing the risk of tampering and maintaining freshness without compromising the integrity of the package. Furthermore, shrink film food grade is resistant to punctures and tears, making it ideal for protecting delicate foods during transportation and handling.

Environmental considerations are also integral to the design of shrink film food grade. Many variants are produced from materials that are recyclable or biodegradable, aligning with sustainability goals and reducing environmental impact. Its lightweight nature contributes to cost-effectiveness in terms of shipping and storage, as it minimizes overall packaging weight while maximizing load efficiency.

In summary, shrink film food grade combines safety, durability, and eco-friendliness, making it an indispensable solution for preserving the quality and prolonging the longevity of a wide range of food products. Its ability to provide an attractive, protective barrier in a cost-efficient manner underscores its significance in modern food packaging applications.

Releated Product

Inquiry